PROCESS

We are a fully vertically integrated unit, participating in and controlling all stages of production and distribution of our products.

OLIVE HARVEST

Step 1

SPREADING THE NETS

First, nets are laid out and spread around the olive trees.

Step 2

BRANCH CUTTING & BEATING

Suitable branches full of olives are cut first. Then, using the beating method, either traditionally with plastic sticks or using modern electric beaters, the fruit is detached from the branch without damaging the valuable olives.

Step 3

COLLECTION AND STORAGE

The olives collected in the nets are gathered and placed either in jute sacks, large bags or perforated bins to ensure that the olives remain alive and able to breathe until they are transported to the mill.

Step 4

TRANSPORTATION

Transportation takes place on the same day to the factory in order to avoid any degradation in the quality of the fruit and to preserve its vitality.

OLIVE OIL PRODUCTION

Step 1

CLEANING – WASHING THE OLIVES (OR FRUIT)

The olive fruit is placed in a stainless steel hopper, from where it is transported via cylindrical belts to the defoliator to remove leaves and foreign matter and then washed in a washing machine.

Step 2

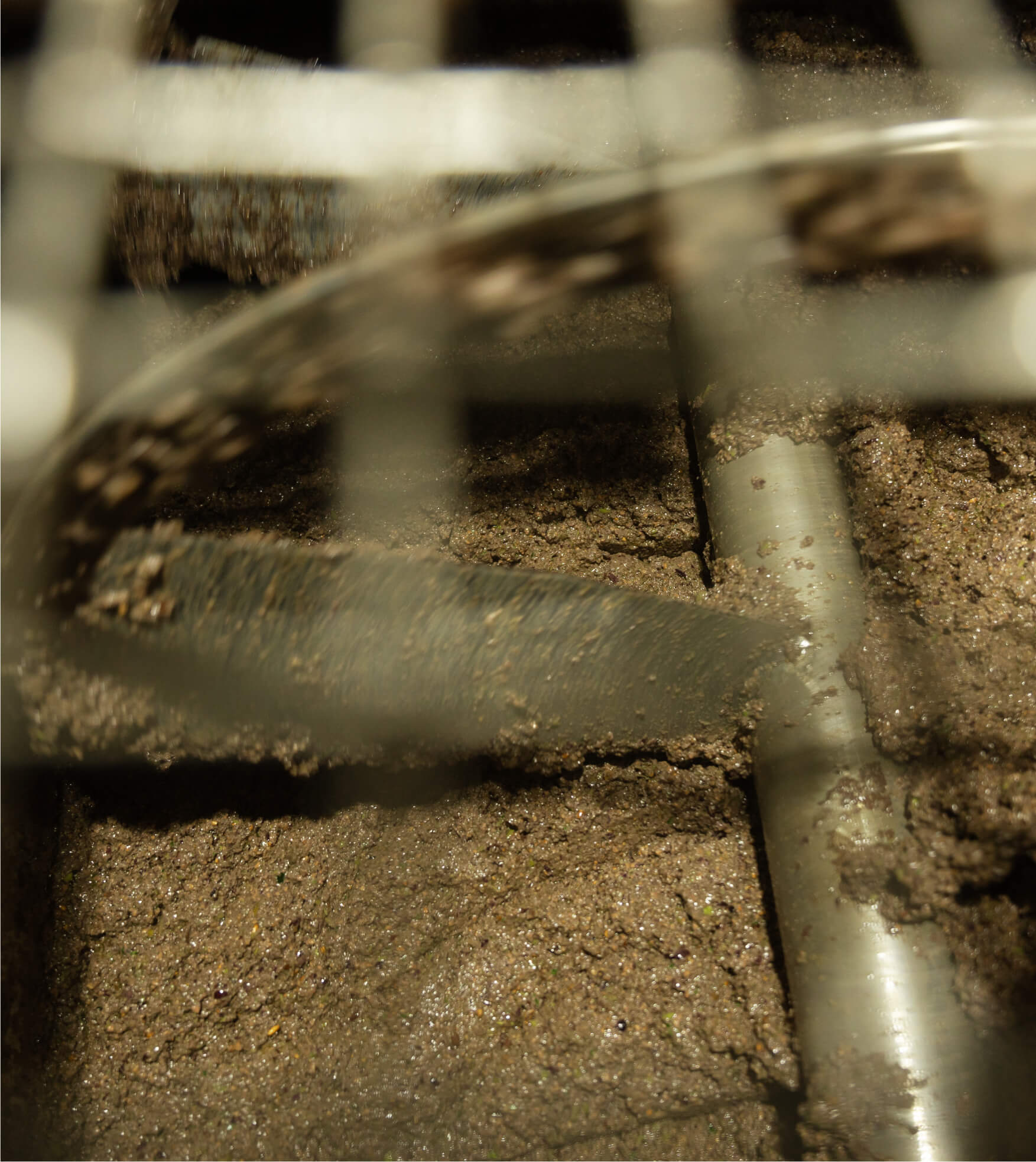

OLIVE CRUSHING & MALAXATION

The olives are crushed using special stainless steel crushers along with the pit and then transferred to malaxers where they are homogenized to form a paste. During malaxation, microscopic oil droplets are released from the olive cells at a temperature of 25–28°C for approximately 30 minutes. This process is called cold extraction.

Step 3

CENTRIFUGATION PROCESS

The homogenized paste is transferred to a two-phase centrifuge, decanter, where the olive oil is separated from the solid and liquid residues.

Step 4

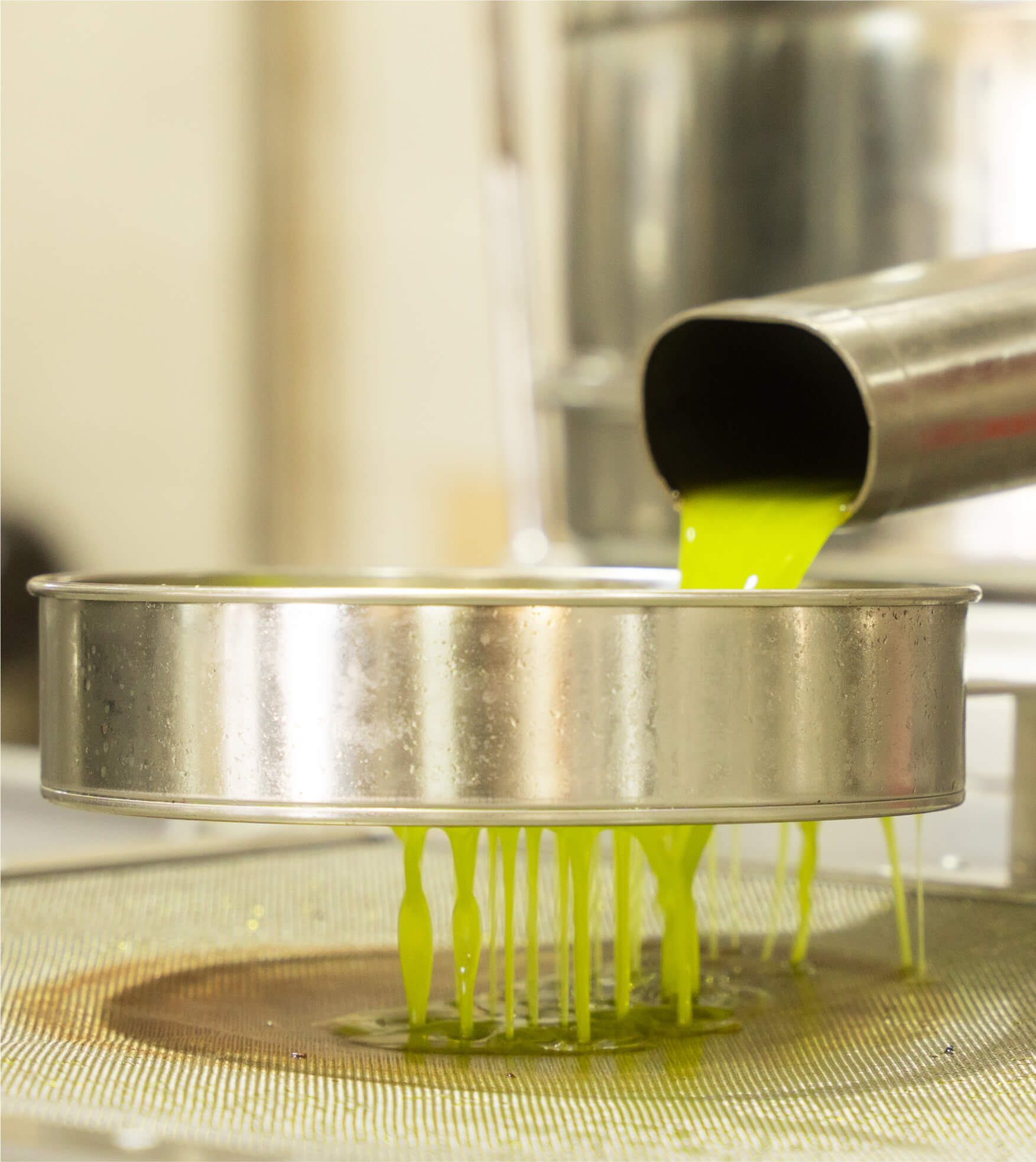

FINAL OLIVE OIL SEPARATION

At this stage, the olive oil passes through separators, where with the addition of a small amount of water, the remaining residues are removed. The result is an extra virgin olive oil with a golden-green color, clear texture and brilliant shine, completing the olive oil production process.

Step 5

OLIVE OIL STORAGE

Following traceability procedures, the olive oil is stored in stainless steel tanks with a capacity of 30 – 50 tons under optimal storage conditions at approximately 18°C. Each tank undergoes all necessary specialized analyses in accredited chemical laboratories.

Step 6

STANDARDIZATION

After storage, the olive oil is filtered to ensure longer shelf life, while preserving its nutrients and freshness. Nitrogen is added to the tanks for enhanced preservation and vitality. Finally, in compliance with strict sanitary protocols, standardization takes place in a separate, specially designed bottling area, where the olive oil is packaged in carefully selected containers ranging from 50ml to 5lt. This process preserves its taste and aroma, ensuring it reaches the final consumer in perfect condition.

OUR PRODUCTS

AENAON

EXPLORE IT

0 3